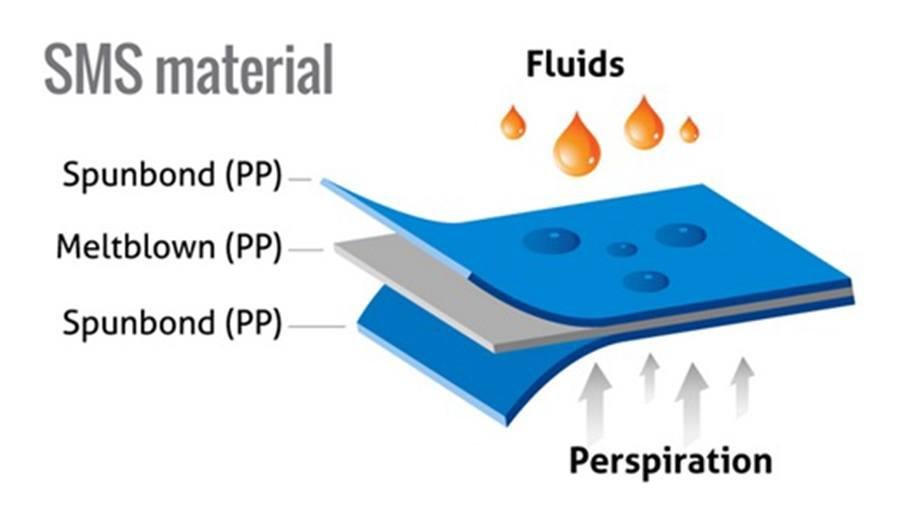

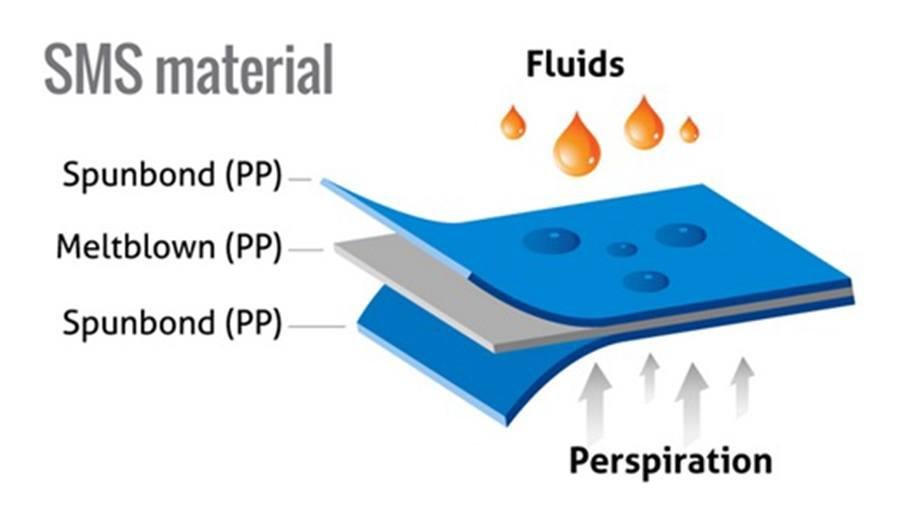

Nonwovens are formed by intertwining fibers or filaments using mechanical, thermal or chemical methods, thereby bonding sheets or web structures together. Nonwovens are usually made of composite or synthetic materials such as polypropylene. Spunbond - Meltblown - Spunbond or SMS is the most commonly used medical nonwoven fabric in the industry.

SMS materials are made by combining spunbond nonwovens and meltblown nonwovens. By layering the two together, manufacturers can leverage the best of both products to create a material with high tensile strength, excellent barrier properties, breathability, softness and light weight.

Spunbond – the process of dispersing spun fibers into a web by means of a deflector or an air stream, it is a thermal bonding method that does not use any chemicals and has long been used in the production of diapers, protective clothing, hygiene products and more.

Meltblowing – The process of blowing hot air onto molten thermoplastic resin, which is extruded through a linear die containing hundreds of holes, resulting in the formation of a fine-fiber, self-adhesive nonwoven web. Meltblown products are ideal for making absorbent materials such as filters or wipes.

Why are SMS nonwovens suitable for the medical industry?

Barrier protection, light weight, breathability, abrasion resistance, absorbency, and all other properties make SMS materials ideal for use in the medical industry. Manufacturers produce a variety of medical products, including gauze, wound care products, surgical gowns, caps, masks, and more, all using SMS material. One of the main advantages of using SMS medical nonwovens is that they can be produced at low cost, so it is economical to produce disposable medical products. Disposable SMS products reduce the possibility of doctors and patients spreading infection and reduce the chance of contamination.

Selection of SMS material

SMS medical nonwovens are available in different types with different thicknesses. Depending on the thickness, the material may be better suited for specific products and applications.

Thin SMS Products – Thin SMS are less bulky but still waterproof and breathable for baby diapers, sanitary napkins and pads.

Medium Thickness SMS Products - Medium Thickness SMS is mainly used in the medical industry. This material is larger than thin SMS, creates an effective fluid barrier, and offers greater abrasion resistance. It is used in surgical gowns, gauze, bandages and other medical and surgical products.

Thick SMS Products - The thickest SMS products are commonly used in different types of gas and liquid filters or oil absorbent products.

Hefei C&P uses high-quality SMS materials to make surgical drapes, surgical gowns, gauze, surgical masks, isolation gowns and other disposable products you need. We will provide the most suitable raw materials and high-quality products in the shortest time to serve our customers.